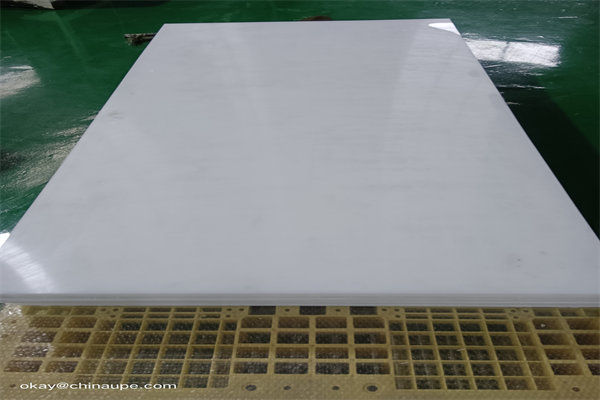

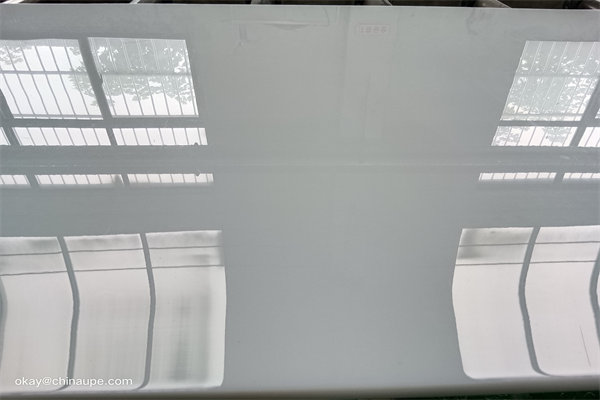

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white. See full list on usplastic.com

High density polyethylene (HDPE) resins from LyondellBasell are thermoplastics made from the polymerization of ethylene in gas phase, slurry or solution reactors. Polymerization takes place under low-pressure nditions with the support of catalysts. HDPE is characterized by a linear polymer chain with few branches, and ntains smaller amounts

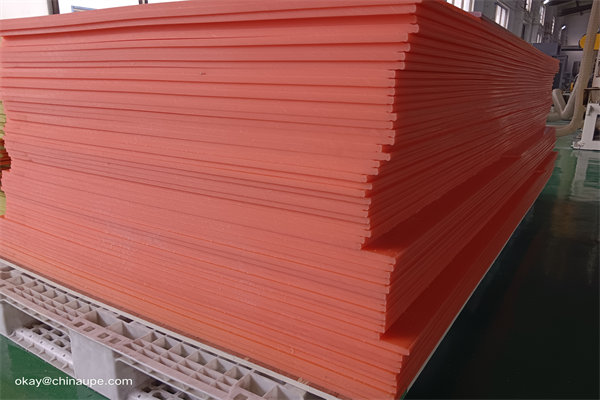

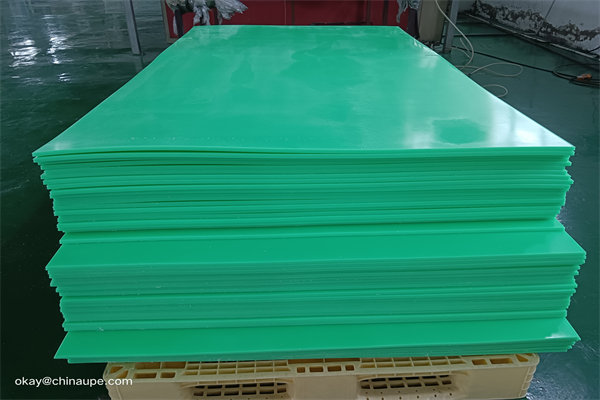

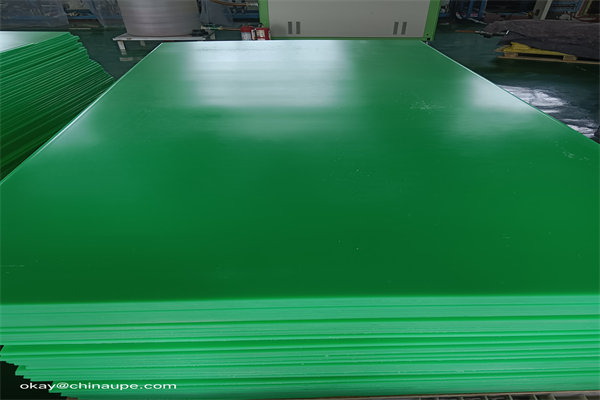

High Density Polyethylene (HDPE) also known as PE100 is a rigid high impact strength sheet. Black polyethylene sheet is stabilized against ultraviolet light and resistant to rrosion in both hot and ld extremes. Widely used in the mining, oil/gas, agriculture, marine, RV, chemical storage and food industries, ite can be custom manufactured to suit many applications.

HDPE (High Density Polyethylene) HDPE (High-density polyethylene) is a thermoplastic derived from petroleum. It is a temporarytile product that is extremely strong, impact resistant, and exhibits a low efficient of friction. HDPE offers great strength, affordability, and environmental friendliness, all of which make it the preferred plastic

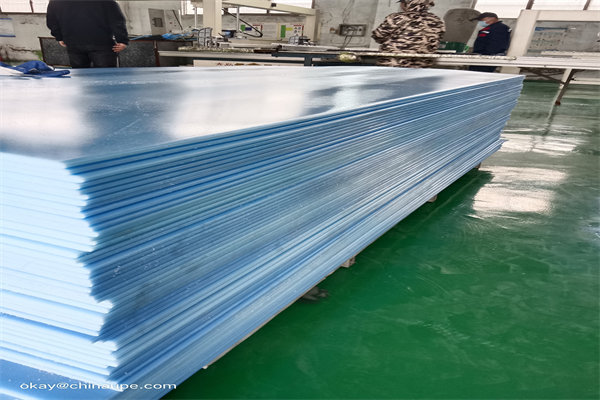

Polyethylene, a polyolefin, is the largest volume thermoplastic polymer used today. It is available in a wide variety of grades and formulations that have an equally wide range of properties. In general, polyethylene’s are characterised by toughness, excellent chemical resistance and electrical properties, low -efficient of friction, near zero moisture HENAN OKAYorption, lightweight and ease of processing.

Overall, HDPE offers excellent impact resistance, is lightweight, has low moisture HENAN OKAYorption, and has high tensile strength. It is also non-toxic, non-staining, and meets FDA and USDA certification. This makes HDPE ideal for food processing. HDPE is available in sheet, strip, rod, tube, and film.

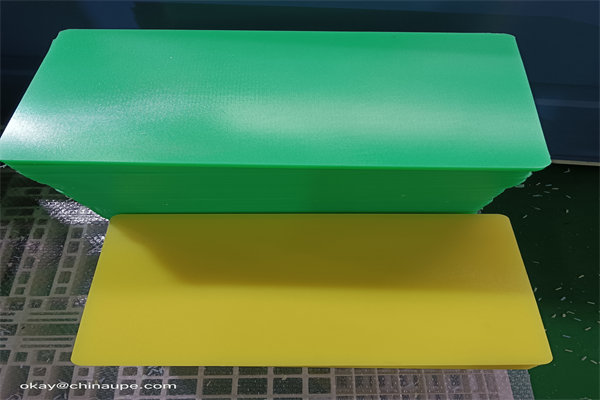

High-Density Polyethylene (HDPE) plastic lumber is a strong and durable building material that can be customized for a wide variety of mmercial, residential and structural solutions.

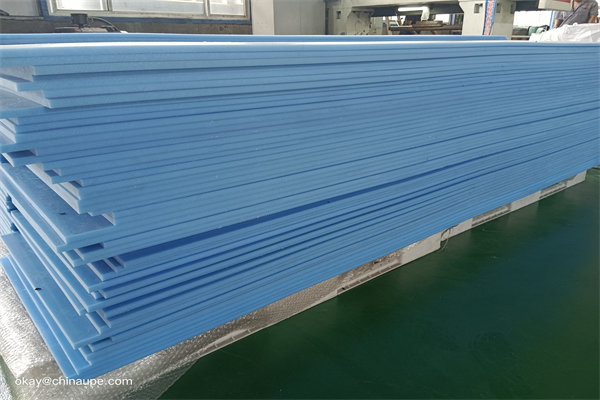

HDPE high density polyethylene (PE300) has excellent impact strength, even at temperatures as low as -30ºC. upled with low efficient of friction and ease of fabrication, HDPE high density polyethylene is widely used in automotive, leisure and industrial applications and is paularly suitable for the fabrication of tanks, silos, hoppers etc.

PVC has a high strength-to-weight ratio, is insect-resistant, and has the optimal density for superior stiffness, impact and fastening. Endurabond™ has premium structural support and surface adhesion characteristics. Unlike wood or metal alternatives, our outdoor building materials do not rust, rrode, rot, delaminate or splinter.

HDPE (high density polyethylene) is available in sheet and rod for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to fabricate and weld using thermoplastic welding equipment and is an excellent choice for fabricated water tanks and chemical tanks.

High-density polyethylene plastic (hdpe) can be used in many applications namely: Buffet lines, such as restaurant buffets, portable plastic cutting board stations for events. Butcher blocks in mmercial applications such as a local fish market or meat unter. nsumer and mmercial cutting boards for cutting food.